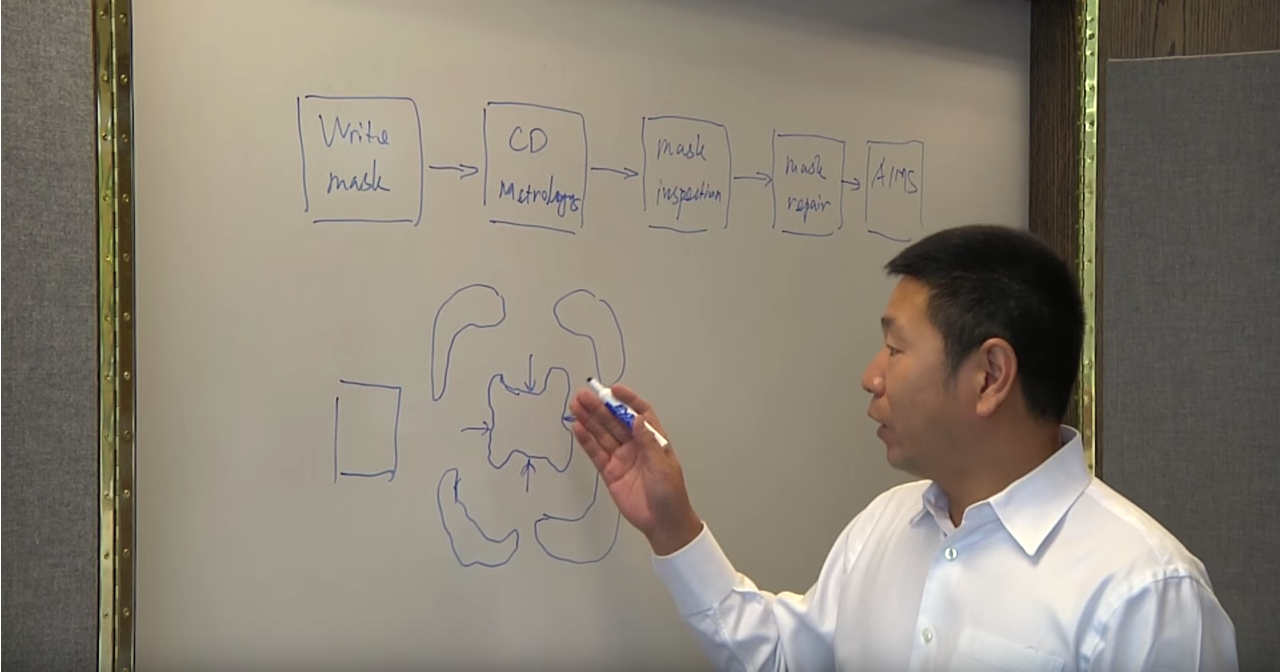

Leading-edge devices are using increasingly more complex mask shapes to attain the required wafer shapes with adequate resilience to manufacturing variation. When mask shapes were largely Manhattan features where mask variation translated to wafer variation equally, determining disposition of mask discrepancy from mask design was largely a function of measuring critical dimension (CD) on mask. Today, with increasing reliance on complex rectilinear or curvilinear shapes with sub-resolution assist features on mask, determining disposition of mask discrepancy requires wafer analysis. The ultimate check – test-printing the wafer – is difficult in the mask shop. Equipment that performs aerial-image analysis is available in the mask shop, but is expensive and resource-intensive, particularly for EUV masks. Wafer aerial simulation of mask contours extracted by CD-SEM provides a practical alternative as the first filter to determine whether differences on mask are material for wafer performance.

TrueMask® WPA (wafer plane analysis) is a GPU-accelerated aerial simulation tool that integrates with mask CD-SEM systems to provide fast, highly accurate and highly repeatable CD metrology for complex and curvilinear mask shapes for both 193i and EUV masks. TrueMask® WPA enables mask shops to leverage existing CD-SEM equipment to identify mask-level CD and defect issues that will impact the wafer. TrueMask® WPA uses D2S GPU-acceleration technologies to provide aerial image simulation of 2D contours extracted by CD-SEM machines – and account for EUV mask 3D effects – at interactive speeds, and at a fraction of the cost of conventional aerial imaging techniques.